Origins of the PVT Hybrid Module Concept

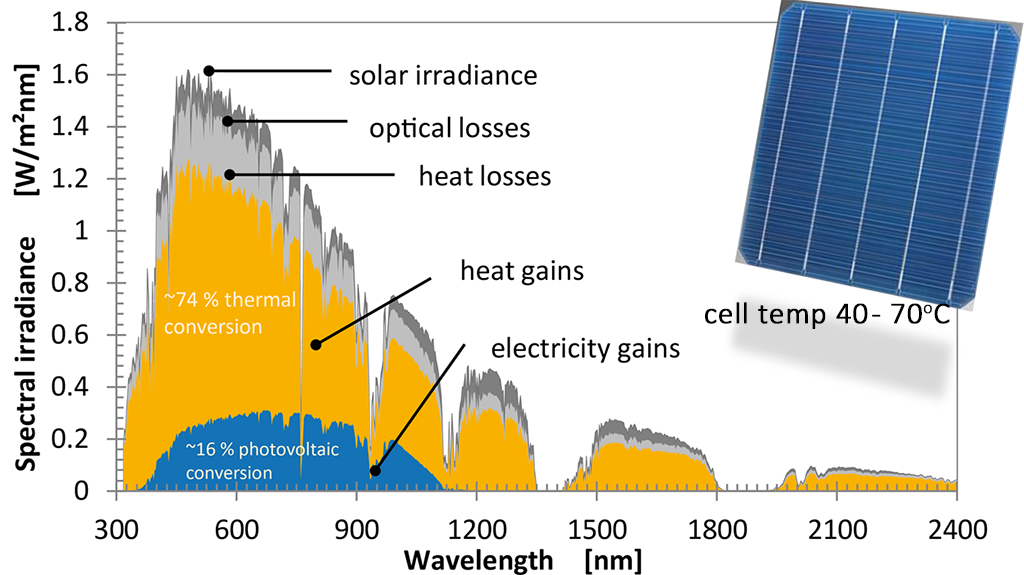

Analyzing the spectral properties of a liquid crystal photovoltaic (PV) cell reveals that only a small portion of the solar spectrum is used for conversion into electricity (blue in the graph below), while the remaining, dominant part (orange) is converted into heat. Based on scientific analyses, in particular by Patrick Dupeyrat, Christophe Ménézo, Harry Wirth, and Matthias Rommel [1] we know that approximately 10% of solar radiation incident on a photovoltaic cell is reflected and cannot be utilized. Only about 17% of the remaining 90% of radiation absorbed by the cell can be converted into electricity, while as much as 73% can be converted into thermal energy.

[1] Source: Patrick Dupeyrat, Christophe Ménézo, Harry Wirth, and Matthias Rommel. “Improvement of PV module optical properties for PV-thermal hybrid collector applications.” Solar Energy Materials and Solar Cells, Vol. 95, Issue 8.

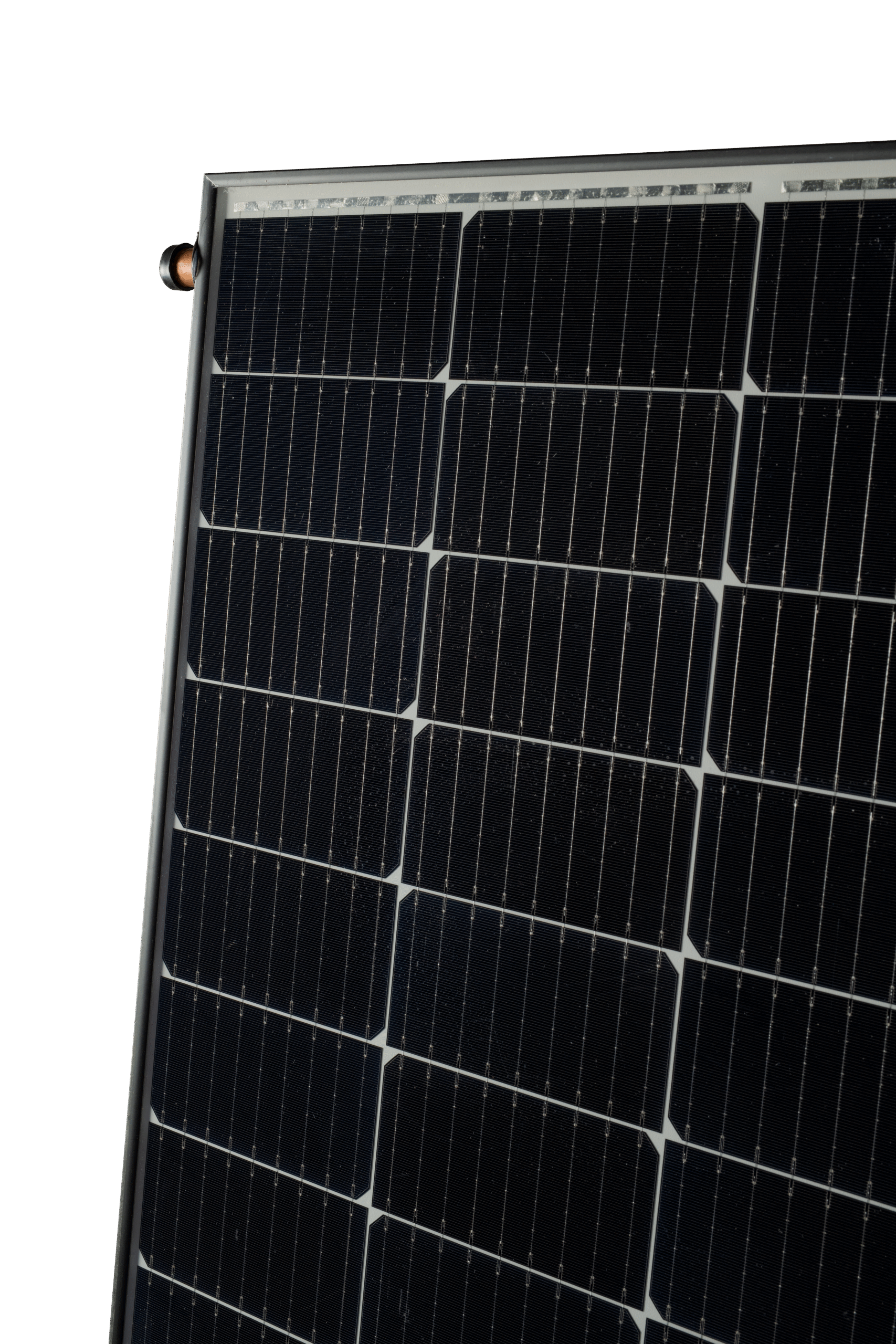

Spectral properties of PV compared to PVT

Therefore, it can be said that in standard silicon solar cells (PV), thermal power remains unused, which negatively impacts electrical efficiency (open-circuit voltage drop, reduced efficiency at the point of maximum power). Therefore, preventing these phenomena by developing a solution that optimally utilizes both forms of energy (electrical and thermal) simultaneously has been a key motivation for many teams of scientists and engineers worldwide. This solution turned out to be the OMEGA hybrid (PVT) module, which utilizes the radiation spectrum and its intensity to the greatest extent possible 24/7.al” and “horizontal”

Design and advantages of Omega-type PVT absorbers

Camel Solar, in collaboration with the Plasma R&D Center, has been pursuing research and development efforts to improve the efficiency of PVT collectors for many years. Currently (since July 2, 2025, following the transfer of intellectual property rights from Camel Solar to Calores Sp. z o.o.), key R&D work in the field of PVT and PVT-based heating systems is being successfully continued and expanded by Calores Sp. z o.o. The result is a unique PVT collector with a high level of innovation.

The groundbreaking nature of Calores PVT modules has been confirmed by independent research laboratories in terms of key parameters monitored in real time. The thermal and electrical characteristics of the PVT modules were simultaneously measured. Tests conducted on the PVT solar collector by the Swiss company SPF included: efficiency, heat loss coefficient, dependence of heat loss on temperature and wind speed, effective thermal capacity, dependence of lossless efficiency on wind speed, and radiation losses.

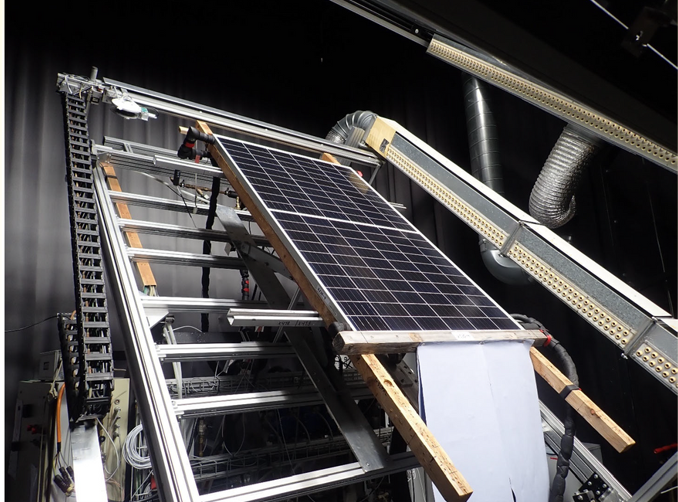

Here a photo from the SPF with PVT on the test bench.

These tests are a crucial part of the PVT technology innovation process, successfully verifying our scientific and technical assumptions and confirming that the goals of increasing PVT collector efficiency through the innovative OMEGA technology, as well as the goals of producing advanced PVT panel models, have been achieved. The most important R&D results for PVT modules include:

The spectacular result of many years of R&D work in the form of the high-efficiency Calores-PVT collector consists of the following partial innovations:

Innovation 1

Development of a thermally conductive nano-binder and its application in PVT systems: The binder enables improved heat transfer from the back foil to the aluminum absorber (in collaboration with Prof. Dr. Hab. Anka Trajkowska Petkoska’s work included

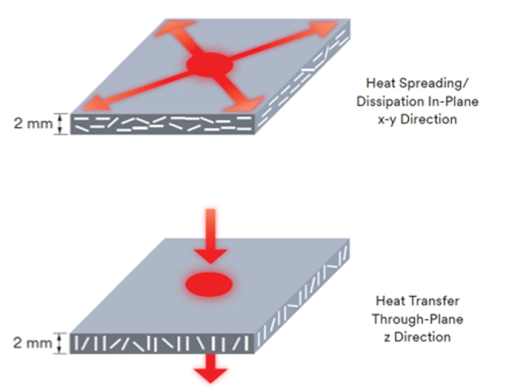

The need to develop a thermally conductive yet electrically insulating binder was more than necessary for PVT modules. Properly connecting the PV and T components across the entire contact surface is crucial due to: improved thermal conductivity, improved heat dissipation, electrical insulation, high dielectric strength and breakdown voltage, compensation for differences in thermal expansion between the Tedlar plate and the OMEGA absorber, no risk of splitting of both components over long periods of use, the use of lighter components, low-density fillers, reduced heat loss, and reduced susceptibility to corrosion.

The need to develop a thermally conductive yet electrically insulating binder was more than necessary for PVT modules. Properly connecting the PV and T components across the entire contact surface is crucial due to: improved thermal conductivity, improved heat dissipation, electrical insulation, high dielectric strength and breakdown voltage, compensation for differences in thermal expansion between the Tedlar plate and the OMEGA absorber, no risk of splitting of both components over long periods of use, the use of lighter components, low-density fillers, reduced heat loss, and reduced susceptibility to corrosion.

Innovation 2

Developing an anti-corrosion coating on the copper pipe that guarantees high corrosion resistance of the pipe’s inner surface, which in turn enables direct circulation of chlorate or salty pool water through the PVT collector.

Improved applicability and market adaptability of PVT technology thanks to differentiation into VERTICAL and HORIZONTAL modules

An important part of the R&D work was also the development of two types of PVT modules with different orientations: horizontal and vertical. Offering both vertical and horizontal options makes it easier for customers and installers to tailor their PVT system design to the specific installation site and climatic conditions, and to optimize the system’s performance and profitability year-round.

The technical and practical rationale for horizontally oriented PVT panels includes the following aspects:

The most important technical and practical reasons for vertically positioning PVT panels include the following: