Why Conventional PV Does Not Fully Utilize the Potential of the Sun

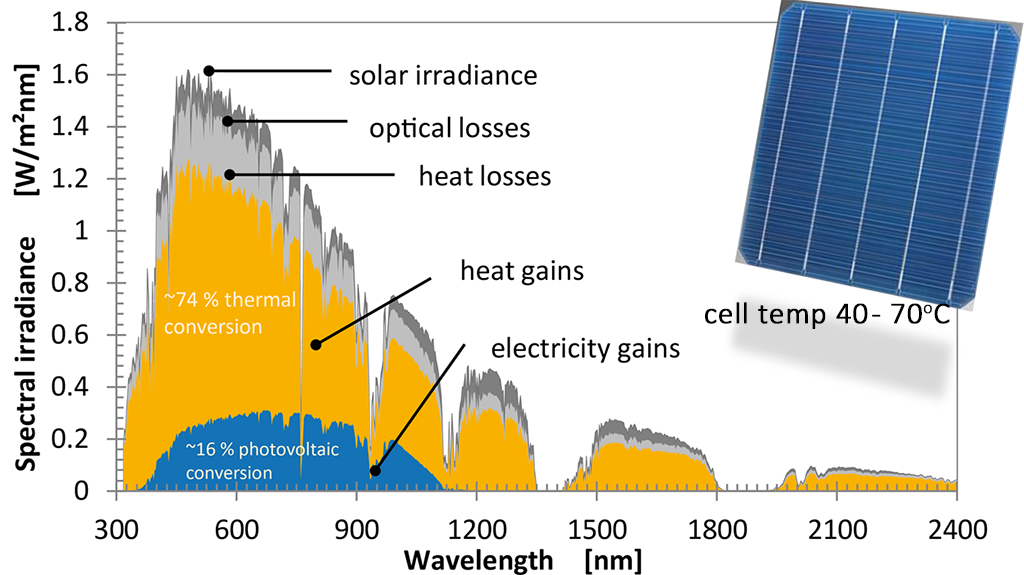

Analysis of the spectral properties of crystalline photovoltaic cells shows that only a small portion of solar radiation is converted into electrical energy. The vast majority of the energy is converted into heat.

Scientific studies indicate that:

In standard PV modules, this thermal energy remains unused, additionally reducing electrical efficiency as module temperature increases.

The Answer: OMEGA-Type Hybrid PVT Modules

Camel Solar, in cooperation with the Plasma research and development center, has been conducting R&D work for many years aimed at improving the performance of PVT collectors.

Following the transfer of intellectual property rights from Camel Solar to Calores Sp. z o.o., key R&D activities in the field of PVT technology and PVT-based district heating systems are now successfully continued and further developed by Calores Sp. z o.o.

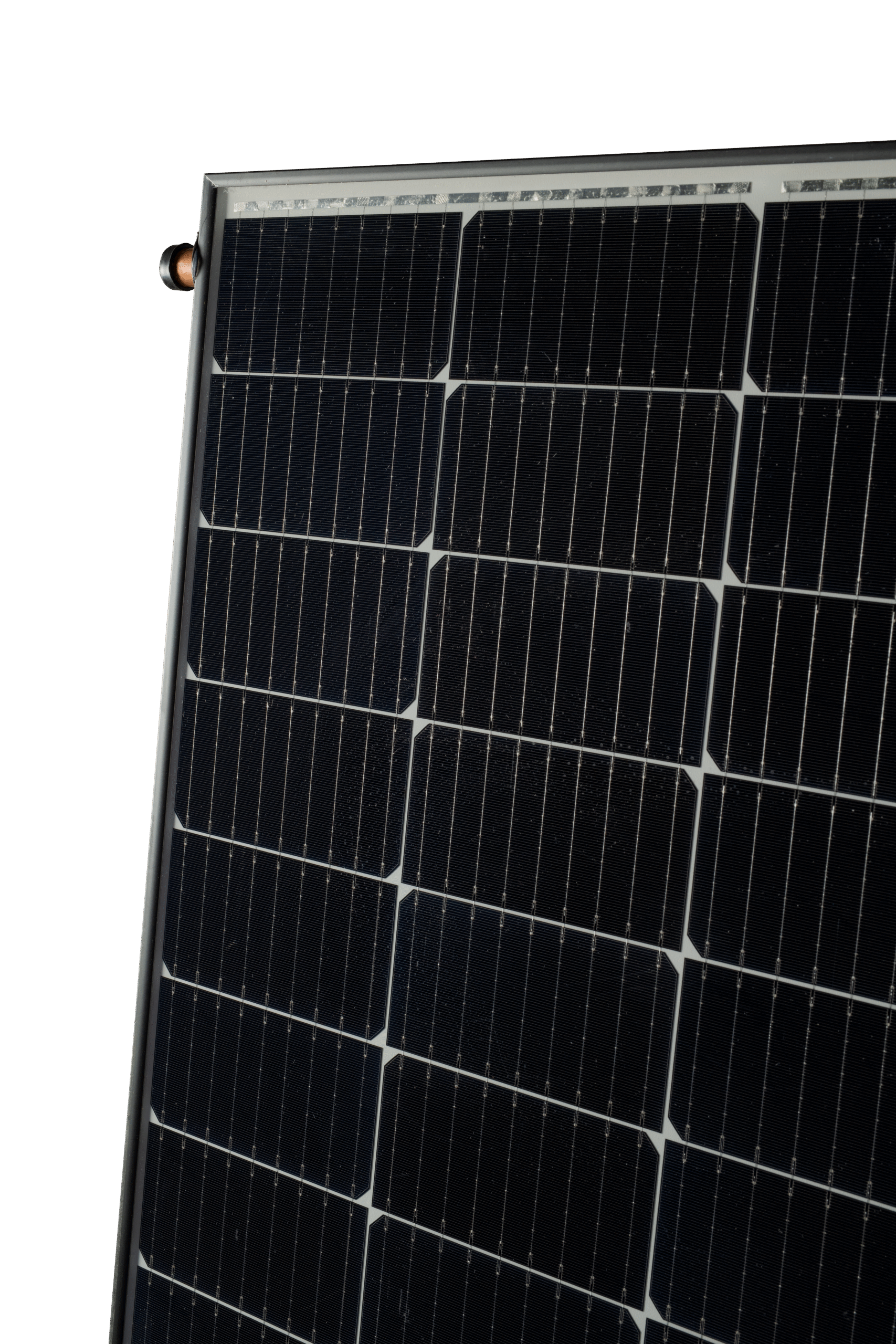

The result of these efforts is a unique, highly innovative PVT collector, representing the outcome of long-term, consistent research and development work.

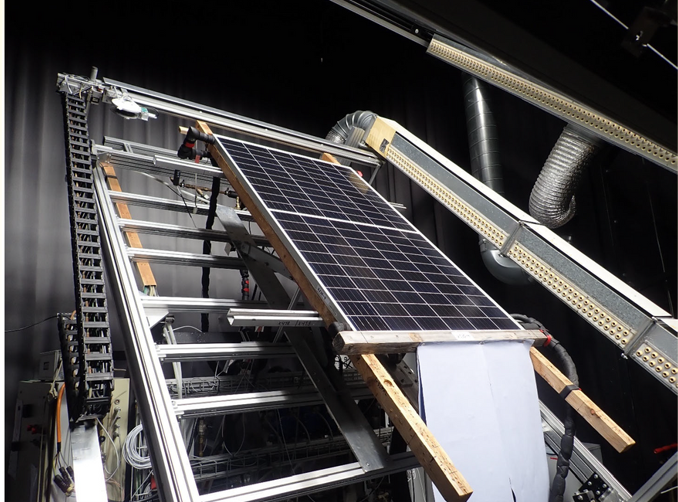

Here a photo from the SPF with PVT on the test bench.

Independent Validation of PVT Technology

The breakthrough nature of Calores PVT modules has been confirmed by independent research laboratories through tests involving simultaneous real-time measurement of key thermal and electrical parameters.

Tests conducted on the PVT solar collector by the Swiss company SPF included, among others:

Independent Validation of PVT Technology

These tests represent a critical element of the PVT innovation process. They successfully verified our scientific and technical assumptions and confirmed that the objectives related to increasing PVT collector efficiency through the innovative OMEGA technology, as well as the capability to manufacture advanced PVT panel models, have been achieved.

The most important outcomes of the R&D work on PVT modules include:

The outstanding result of this long-term R&D process — in the form of a high-performance Calores hybrid PVT module — is based on a series of partial innovations covering both structural and process-related solutions.

Technological Innovations

1. Nano Thermal Interface Compound

A specially developed compound enables efficient heat transfer from the rear layer of the PV module to the aluminum absorber, while maintaining full electrical insulation. This solution increases system durability, improves heat dissipation, and compensates for differences in thermal expansion between materials.

2. Anti-Corrosion Coating for Copper Pipes

The use of an internal anti-corrosion coating allows for the direct circulation of even pool water or saline water, significantly expanding the range of possible PVT module applications.

Market Adaptation: Horizontal and Vertical Modules

To increase design flexibility and year-round efficiency, PVT technology is available in both horizontal and vertical configurations.

Horizontal modules are particularly suitable where the following factors are critical:

Vertical modules offer: