Technical Parameters of the ML 450/1200 PVT Module

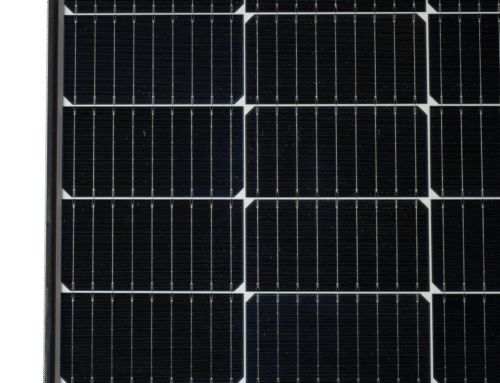

The ML 450/1200 PVT module is a hybrid solar panel that simultaneously generates electricity and thermal energy. This module boasts high electrical efficiency thanks to its multi-busbar monocrystalline cells. This module can be considered a high-performance product. Its efficiency is 20.7%, which stands out beyond electrical efficiency of many typical PVT modules. The overall efficiency and thermal output are comparable to standard market solutions in PVT technology.

Electrical efficiency: This model boasts a PV efficiency of approximately 20.7%. Typical PVT modules typically have electrical efficiencies ranging from 8% to 12%, or slightly higher in demanding applications. This relatively high efficiency of approximately 20.7% is achieved thanks to high-efficiency monocrystalline cells and multi-busbar technology.

Thermal power: The module delivers 1218 Watts of heating power from a surface area of approximately 2.16 m², corresponding to a thermal efficiency of approximately 56-65%.

Total efficiency: For PVT systems, this is the sum of the electrical and thermal efficiencies, typically ranging from 65% to 76%. Considering the electrical and thermal power values listed above, the PVT ML 450/1200 model exceeds commercially available PVT modules in this respect.

Temperature coefficients*: They are consistent with comparative testing: a degradation of electrical power of approximately 0.36%/°C is typical, and a degradation of thermal efficiency of approximately 0.33%/°C is also within expected standards.

*Temperature coefficients indicate the reduction in electrical and thermal power due to temperature changes.

Power Output (PV) – 450 Wp: This is the maximum power output that photovoltaic cells can produce under standard test conditions (STC). This parameter determines the power of the module’s photovoltaic component.

Heat Output 1218 Wt: The module’s thermal component can produce up to 1218 watts of thermal energy.

Copper-Aluminum Harp Heat Exchanger: The thermal absorber utilizes copper tubes, which conduct heat perfectly, improving the module’s thermal efficiency. Omega technology combines the absorber harp with aluminum strips that capture solar heat.

Electrical parameters under standard test conditions (STC)

-

maximum power (450 Wp),

open-circuit voltage (Voc) of 48 V - napięcie w obwodzie otwartym (Voc) 48 V

- short-circuit current (11.55 A Isc)

- maximum power voltage (41.0 V)

- maximum power current (10.98 A)

The above parameters characterize electrical performance under standardized solar radiation and temperature conditions.

Dimensions and weight: The module measures 2094 x 1038 x 35 mm, has a surface area of 2.16 m², and weighs 33 kg, which determines its physical dimensions and mass.

Heat exchanger characteristics: 6 mm copper pipe diameter, 20 mm mineral wool insulation, and 1.45 liters of propylene glycol as the heating medium. These parameters describe the thermal fluid circulation system integrated in the module.

Connections and wiring: Single-row connection, IP67 protection, three bypass diodes, and a 4 mm², 0.3 m cable with MC4 or compatible connectors. This indicates the high quality of the electrical connections.

Pv cells and glass: 144 monocrystalline silicon cells cut in half, connected in series with 3.2 mm thick tempered glass, ensuring durability and efficiency.

Standards: The module complies with numerous international standards (EN 12975-1+A1, IEC 61215, IEC 62804, etc.), confirming its proven quality and reliability.

The quality of the PVT 450/1200 module is based on excellence and experience in the industrial production of frame PV modules – ML System, a leader in the building-integrated photovoltaics (BIPV) market in Poland

What achievements define ML System’s position as a leader in the building-integrated photovoltaics (BIPV) market in Poland?

ML System is a leader in the building-integrated photovoltaics (BIPV) market in Poland. The company owes this position to several key features of its technology and a consistently implemented development strategy.

ML System’s distinguishing features in the market include: continuous development focused on practical innovations, a strong research and development base, a recognizable brand with a broad portfolio of advanced technologies, and the ability to produce modules closely integrated with building structural elements that meet high aesthetic and functional requirements. This makes ML System’s technology stand out in the market and earns the trust of investors and architects.

The company has its own advanced research and development center, where it creates and develops unique products based on proprietary technologies, including the world’s first production line for printed photovoltaic cells.

ML System’s innovation is confirmed by numerous patents (21 patents, 17 patents, and 9 pending applications; a list of selected patents is below) and an extensive product portfolio (list below), which provide an alternative to traditional building materials, offering, among other things, high thermal insulation, water tightness, and acoustic insulation.

ML System also conducts research on the use of quantum physics phenomena in medical diagnostics and has launched the world’s first production line of transparent quantum-coated glass that generates electricity, which is part of the so-called “new quantum era” strategy. The development of new ML System technologies, such as Quantum Glass, 2D Glass, and Active Glass, allows it to maintain a technological advantage over the competition.